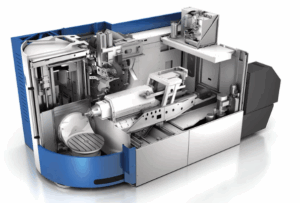

We’re proud to announce the newest addition to our manufacturing floor: the GROB G750—a world-class 5-axis horizontal machining center engineered for complex, high-precision parts.

As our company continues to grow and push the envelope in advanced aerospace manufacturing, investing in cutting-edge technology is a key part of our commitment to Excellence, Quality, and Innovation. The G750 enhances our ability to meet the demanding tolerances and tight lead times our customers expect, all while increasing efficiency and part complexity capabilities.

Why the GROB G750?

-

5-Axis Simultaneous Machining – Perfect for intricate geometries and minimizing setups.

-

Horizontal Spindle Design – Optimizes chip flow and thermal stability, resulting in superior surface finishes and extended tool life.

-

Large Work Envelope – Enables machining of both small precision components and large structural parts on a single platform.

-

Automation Ready – Seamlessly integrates with pallet pools and robotic systems for lights-out machining and 24/7 operation.

-

German Engineering, American Support – A trusted name in innovation and reliability.

What This Means for Our Customers

The GROB G750 strengthens our ability to take on more complex jobs, reduce cycle times, and deliver precision components faster and more reliably. This investment supports our mission to remain a leader in advanced manufacturing and reinforces our commitment to continuous improvement and long-term partnerships with our customers.